Introduction

Every stretcher carries a story—not just of rescue, but of human progress.

From the rough wooden stretchers used in field hospitals to today’s lightweight composite models used in air and sea operations, this equipment has evolved alongside medicine and engineering.

This article traces the development of rescue stretchers from the 19th century to today, highlighting how advances in design, materials, and safety standards have defined modern emergency care.

Early Designs: The Era of Wood and Canvas (19th–Early 20th Century)

The origins of the rescue stretcher lie in 19th-century military medicine.

According to records from the U.S. Army Medical Department Museum, early field medics relied on wooden poles and canvas slings, often improvised from tent fabric or wagon materials.

These primitive designs were heavy, unsanitary, and lacked spinal support, yet they represented a major step forward: recognizing that safe transport was part of treatment itself.

During World War I and II, stretcher construction became standardized.

British and American forces developed foldable wooden stretchers with metal hinges and canvas beds, making them easier to carry and stack. These designs established the structural foundation for modern rescue equipment.

The Metal Revolution: Strength Meets Mobility (1940s–1970s)

By the mid-20th century, metal replaced wood as the dominant material.

As documented by the Smithsonian National Museum of American History, aluminum alloys became widely used in medical and rescue equipment from the 1940s onward due to their strength, light weight, and corrosion resistance.

This era saw several landmark innovations:

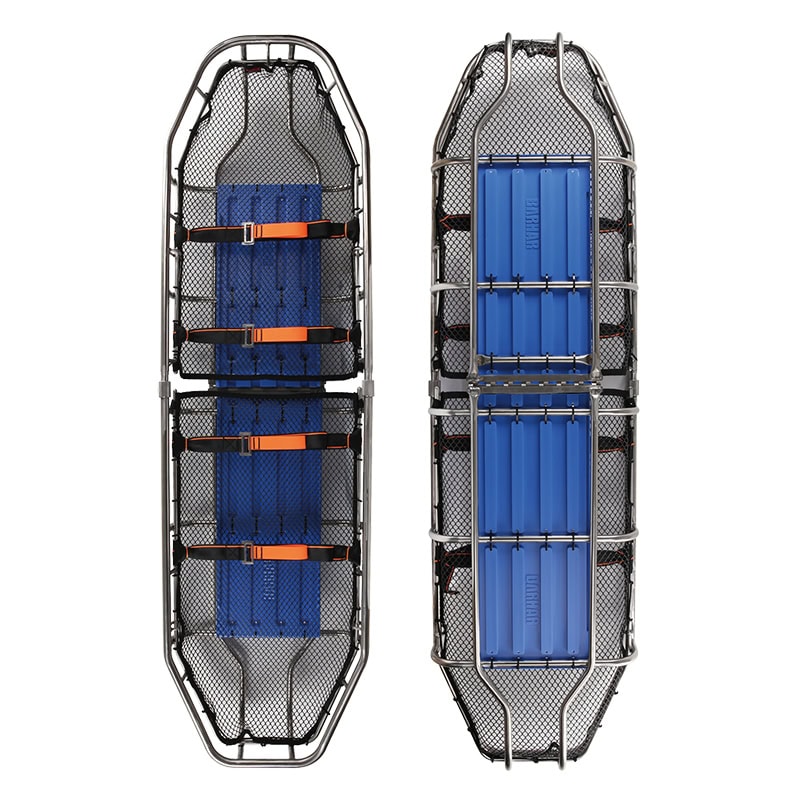

- The Stokes Basket (U.S. Navy, 1945): A wire-frame metal basket stretcher designed for shipboard and air-sea rescues. It became standard equipment for the U.S. Coast Guard and other maritime agencies.

- Wheeled Hospital Stretchers (1950s–1960s): Adjustable, wheeled frames introduced in hospitals and ambulances marked a shift from manual carrying to mechanical transport.

The metal era gave rescuers a new advantage—consistent, durable, and repeatable performance—laying the groundwork for standardized emergency response systems.

Standardization and the Rise of Modern EMS (1970s–1990s)

The 1970s marked the formal birth of modern Emergency Medical Services (EMS).

With this came the first global push for standardized rescue and transport equipment.

In the United States, organizations like the National Fire Protection Association (NFPA) and the Department of Transportation (DOT) established performance criteria for stretchers used in ambulances and field rescue.

The National Institute for Occupational Safety and Health (NIOSH) published several studies in the late 1970s highlighting the risks of poor equipment design and unsafe lifting practices.

Manufacturers responded with:

- Locking mechanisms and adjustable frames.

- Padded surfaces for comfort and vibration reduction.

- Improved restraint and anti-slip systems for stability.

By the 1990s, aluminum alloys, reinforced plastics, and ergonomic design had become the global standard. The stretcher was no longer just a transport tool—it had become a medical device engineered for precision and safety.

Composites and Advanced Engineering (2000s–Present)

The 21st century brought a new era of materials innovation.

Research from the National Institute of Standards and Technology (NIST) on advanced composites such as carbon fiber-reinforced polymers (CFRP) and high-density polyethylene (HDPE) helped shape the next generation of medical and rescue equipment.

Modern stretchers now feature:

- Lightweight composite frames: Up to 40% lighter than aluminum, reducing fatigue during mountain or aerial rescues.

- Enhanced corrosion and flame resistance: Ideal for maritime, firefighting, and industrial environments.

- Modular and collapsible designs: Optimized for helicopter hoists and confined spaces.

Today, many rescue stretchers are designed and tested in compliance with ISO 13485 and CE medical device standards, ensuring structural reliability under extreme load and temperature conditions.

The Future: Sustainable and Smart Design

Rescue technology continues to evolve toward sustainability and intelligent design.

Universities and research institutions, such as the University of Washington’s Department of Rehabilitation Medicine, are studying ergonomics and patient positioning to minimize secondary injury during transport.

Meanwhile, manufacturers are exploring recyclable composites and integrated sensors capable of monitoring load distribution, posture, and vital signs during rescue missions.

These innovations point to a future where stretchers are not only strong—but also data-driven and environmentally responsible.

Why This History Matters

Understanding the history of rescue stretchers helps explain why design standards matter today.

From wooden frames to composite engineering, every improvement has pursued a single goal:

to move patients faster, safer, and with greater care.

At Jiekang Rescue, that legacy continues.

Our stretchers integrate aluminum, HDPE, and composite structures—tested for load, durability, and performance.

All models comply with ISO, CE, and FDA certifications, ensuring consistent quality and global trust.

Each product we build honors more than a century of innovation and the enduring mission to protect life through better engineering.

Conclusion

From crude wooden poles and canvas beds to aerospace-grade composite systems, the evolution of the stretcher is a story of human ingenuity, compassion, and responsibility.

It reminds us that progress in rescue work is not only measured by speed—but by safety, design integrity, and respect for every life carried.

Learn more about modern certified rescue stretchers at Jiekang Rescue.