Introduction

Rescue doesn’t wait for ideal weather.

Ambulances bake in summer heat, mountain calls start below freezing, and coastal ops fight salt and humidity.

Those conditions don’t just challenge people. They stress frames, coatings, joints, electronics—everything your EMS equipment depends on. For context on heat as a workplace risk, see NIOSH’s overview of Heat Stress and Workers and its practical recommendations.

In this guide, we anchor decisions to standards, materials, testing, and maintenance—so environmental durability is built into your buying and validation process, not bolted on later.

1) Why “environment” belongs in your design inputs

Environments vary wildly: ambulance interiors, open terrain, near-shore spray, tropical depots. Each has a different cycle of temperature, humidity, UV, vibration, and contaminants.

Regulators and global guidance already expect you to plan for this. The U.S. FDA’s guidance on Design Considerations for Devices Intended for Home Use (with the full PDF) calls out evaluation of temperature, humidity, vibration, EMC, and power for out-of-hospital use. WHO’s technical resources also emphasize lifecycle management, including environment and preventive maintenance—see WHO Medical Devices Technical Specs resources and the WHO overview of equipment maintenance programs.

2) Temperature: what heat and cold actually do

High heat (summer interiors, desert sun). Metals expand; polymers soften. If coatings and adhesives aren’t specified for the top end of your use profile, you’ll see creep, loosened fasteners, and degraded finishes. For how labs model combined UV–temperature–humidity exposure, review NIST’s Accelerated Weathering Laboratory and the companion AWL operations project—useful when you’re designing or selecting aluminum + coating + polymer stacks.

Low temperatures (alpine, winter callouts). Cold increases lubricant viscosity and can reduce toughness in some plastics, slowing fold/lock actions. Build low-temp impact, low-temp start, and lubricant compatibility into your DVT. For human-factor risk framing in hot/cold stress, NIOSH’s heat stress overview is a practical reference for training and procedures.

3) Humidity and salt: the quiet life-cycle loads

High humidity and condensation accelerate corrosion, undermine coatings, and age adhesives. Near-shore salt spray makes it worse. Two widely used methods help you specify and compare:

- IEC 60068 environmental testing: the family that covers low temp, dry heat, rapid temperature change, constant humidity, mold, and solar radiation. For accessible primers, see Intertek’s explainer on **IEC 60068-2-78 (constant humidity)** and an overview of IEC 60068-2 methods.

- ASTM B117 salt spray: the classic salt fog test for comparing corrosion-resistance of finishes. It’s not a direct life predictor; it’s a comparative screen for protective systems.

Implementation tip: if your gear sees coastal use or ocean shipping, pair IEC 60068-2-78 (humidity) + IEC 60068-2-14 (thermal cycling) + ASTM B117 (salt) to capture the combined effects of moisture ingress, corrosion, and expansion/contraction.

4) Vehicle and out-of-hospital standards that matter to EMS

- ISO 13485 (QMS for medical devices). Sets expectations for design inputs, risk control, and verification—including environment. See the ISO overview page.

- EN 1789 (road ambulances and their equipment). Addresses patient compartment environment, ergonomics, and fixation of equipment under dynamic conditions. A BSI/ANSI preview shows the scope and structure.

- IEC 60601 (medical electrical equipment). If the device includes electronics, consider 60601-1 (basic safety), 60601-1-2 (EMC), and for home/out-of-hospital conditions 60601-1-11. Practical primers: Intertek on IEC 60601-1-11 and IEC 60601-1-2 EMC.

These don’t replace your validation plan. They give you a common language—what to test, and how—so buyers, engineers, and regulators stay aligned.

5) Materials and finishes: specify a system, not a part

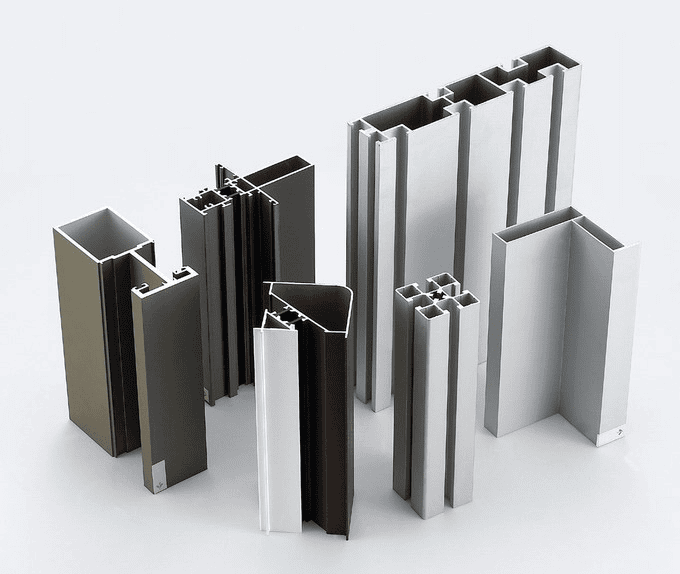

- Aluminum alloy frames (e.g., 6061-T6). Excellent strength-to-weight; pair anodizing + powder coating for corrosion and cleanability.

- HDPE panels. Low moisture uptake, impact-tough, easy to disinfect—ideal for spine boards and water-rescue units.

- Composites (CFR/ GFR). High stiffness with low thermal expansion; watch resin durability under UV + humidity.

For how to structure accelerated exposure (UV–temp–humidity) when comparing material stacks, NIST’s accelerated weathering lab page and a representative publication—A Systematic Approach to Accelerated Weathering of Building Sealants—are solid references for method selection and data interpretation.

6) Test strategy: move environment upfront in DVT/type tests

Build a compact, defensible matrix and make reports traceable:

- High/low temp storage & operational tests; thermal cycling—see an accessible explainer of IEC 60068-2 methods (e.g., -2-1/-2/-14).

- Constant humidity / mold—IEC 60068-2-78 and related parts.

- Salt spray—ASTM B117 for finish system comparisons.

- Vehicle fixation, shock, vibration—align with EN 1789 requirements for ambulance equipment.

- Electrical/EMC (if applicable)—IEC 60601-1-11 for out-of-hospital use + IEC 60601-1-2 for EMC; use FDA’s design guidance to capture labeling/training controls.

7) Maintenance and storage: write environment into the SOP

Real-world life depends on routine care. WHO recommends program-based maintenance with clear roles, schedules, and documentation—see WHO’s maintenance program overview.

Operationally:

- Storage/transport. Dry, ventilated, temperature-stable. Avoid prolonged parking in sealed hot cabins; for ocean freight, manage salt/fog and condensation.

- Post-cleaning. Fully dry hinges and fasteners after wash/disinfection to prevent moisture traps.

- Cold regions. Check fold/lock mechanisms and lubricants for low-temp performance.

- Monthly checks. Fasteners, coating damage, seals; re-coat or replace as needed.

These steps align with FDA’s home/out-of-hospital design guidance: control environmental risks through design, labeling, and user training.

8) Buyer checklist (8 quick questions)

- Does the supplier run an ISO 13485 QMS and retain environment test records (temp/humidity/salt/thermal cycling)?

- Are operating/storage ranges and disinfection compatibility stated in the spec?

- For ambulance use, is fixation and ergonomics aligned with EN 1789?

- If electronics are present, do they meet IEC 60601-1-11 and 60601-1-2?

- Has the finish system been benchmarked by ASTM B117 or equivalent?

- Are key materials (aluminum grade, HDPE, composite) disclosed with coating/UV/humidity data?

- Do you receive maintenance and storage SOPs and climate cautions in labeling?

- Can the supplier share traceable reports or third-party summaries on request?

How we build for climate—Jiekang Rescue

We standardize what you’ve just read:

- Frames & finishes: aluminum + anodizing + powder coat.

- Materials mix: HDPE and composites specified by use case.

- Validation: thermal cycling + constant humidity + salt fog + UV accelerated exposure.

- Documentation: design and production records under ISO 13485; clause mapping against EN 1789 / IEC 60068 / ASTM B117 / IEC 60601.

- Support: clear maintenance SOPs and environmental limits.

If you want to compare stretcher architectures by environment and material, start here: Various Rescue Stretchers.